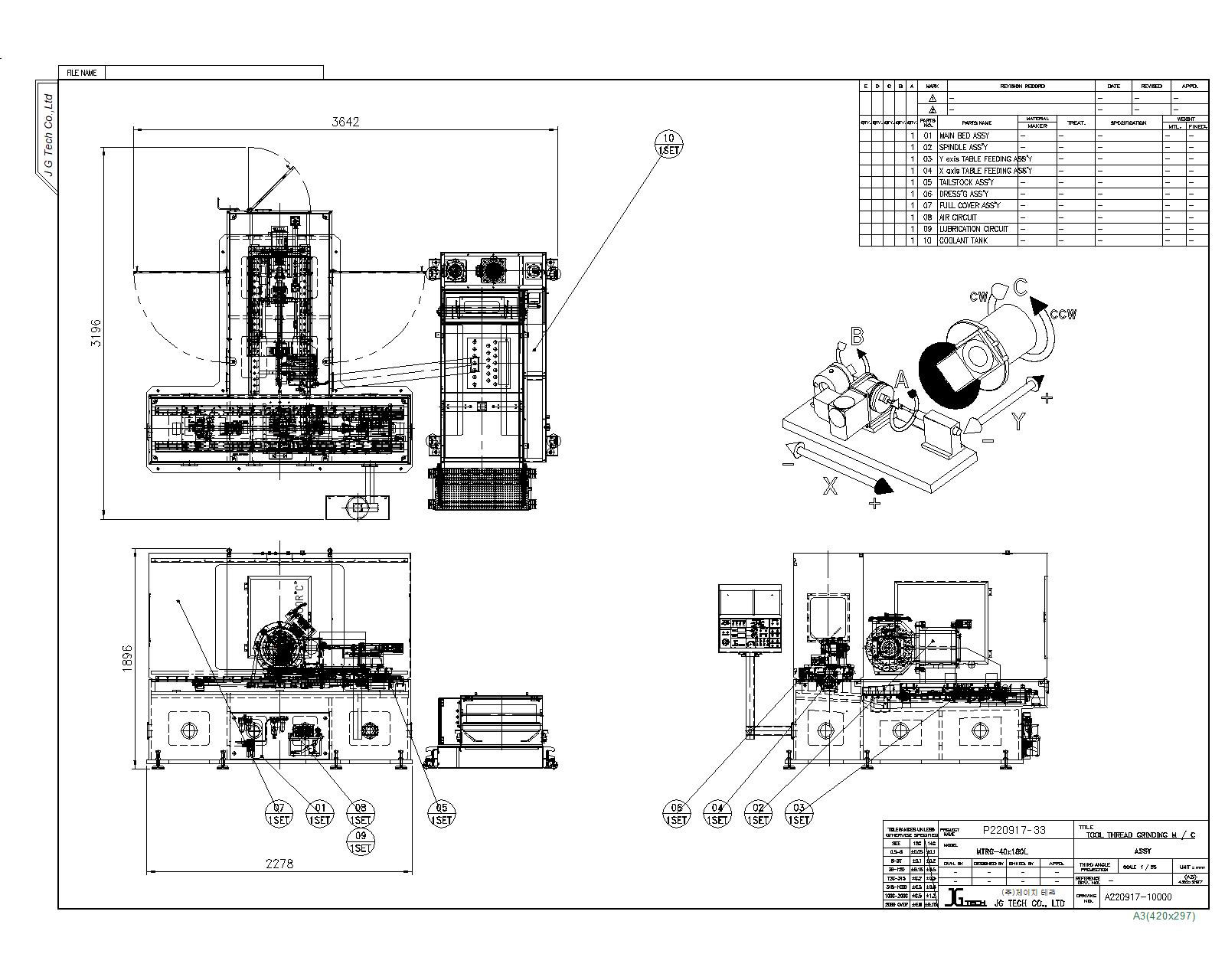

Roll Thread Grinding Machine Development

- Total production period

- September 17th, 2022 ~ October 20th, 2023

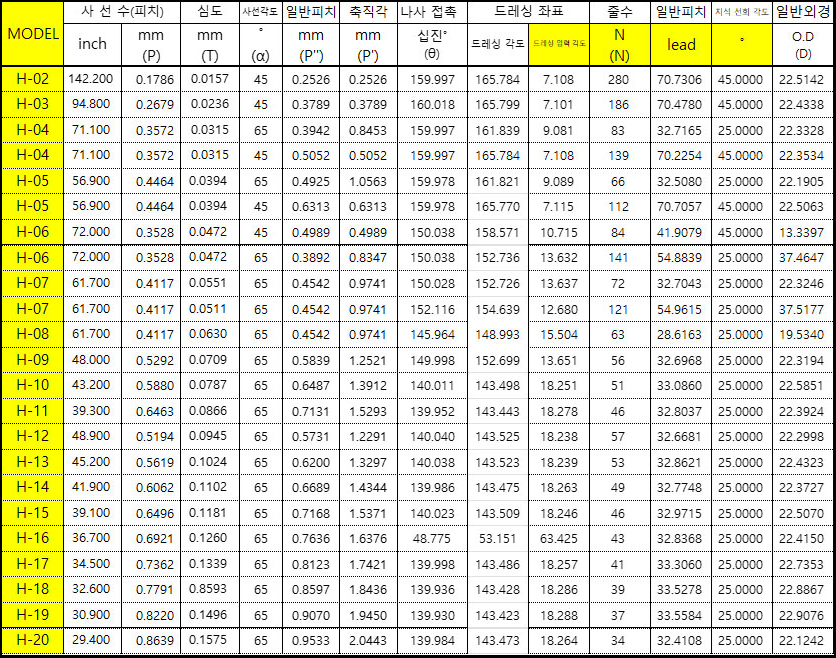

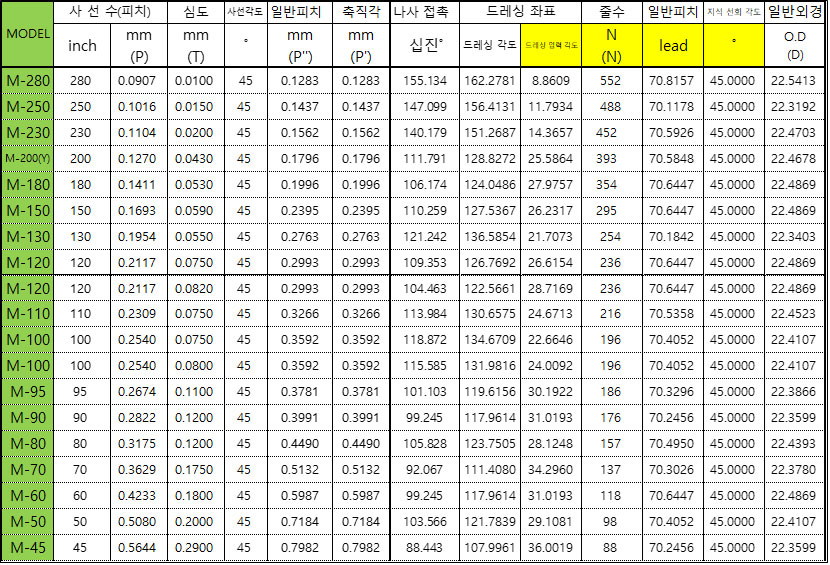

- Technical difficulties

- Pitch, Depth, Diagonal angle, Normal pitch, Transverse pitch, Thread contact angle, Dressing coordinate, Number of lines, lead, Wheel angle, Mathematical function formula between outer diameters.

- Mechanical conditions that satisfy the left-right, top-bottom parallelism between the index spindle center and tailstock center of 0.001mm or less.

- Issue

- Obtain dressing coordinate input angle according to arbitrary wheel turning angle.

- Obtain SHIM values inserted into the housing height and side of the tailstock and perform precise material machining.

- A program that allows you to input touch point values on the line grinding the workpiece.

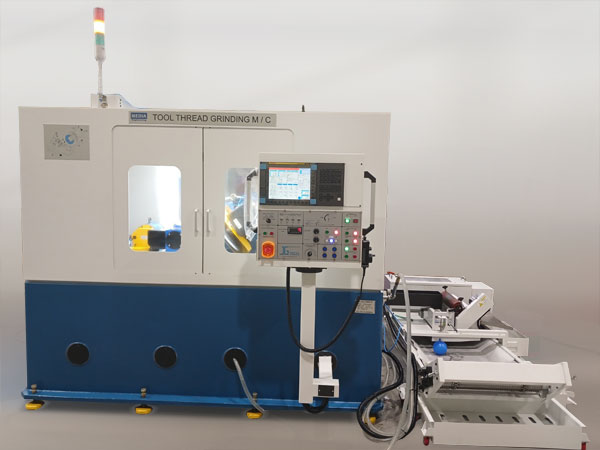

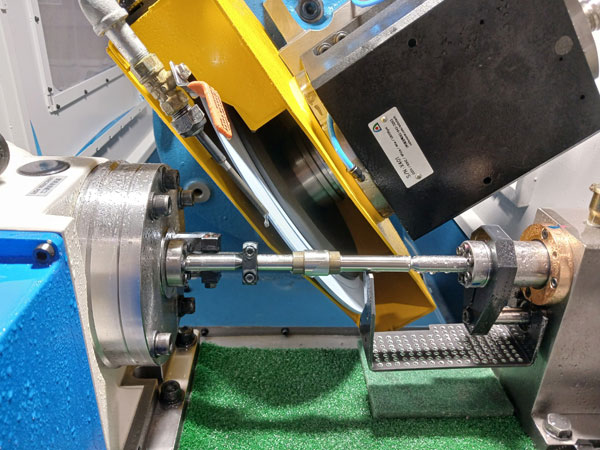

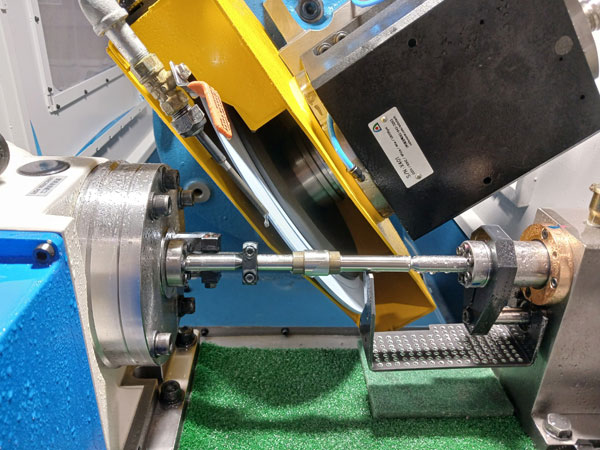

Development pictures

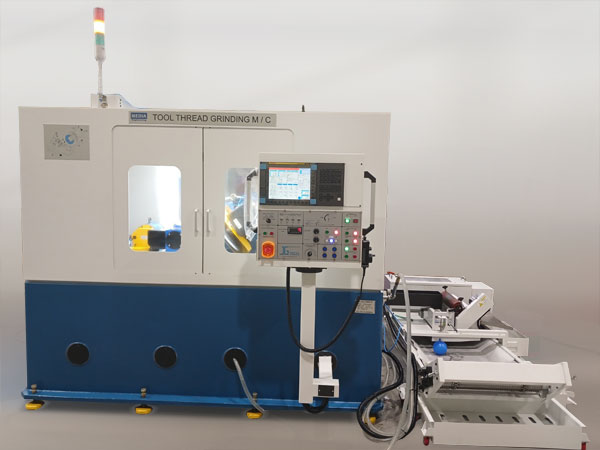

Development completion -1

Development completion -1 Development completion -2

Development completion -2 Material – Before

Material – Before Material - After

Material - After

Specifications

| Description |

Unit |

|

| Capacity |

Max Work Piece Length |

mm |

150 |

| Max Work Piece Diameter |

mm |

∅30 |

| Max Length |

mm |

180 |

| Travel Range |

X-axis |

mm |

600 |

| Y-axis |

mm |

300 |

| A-axis Rotation |

deg |

360° |

| C-axis |

deg |

±45° (수동) |

| Axis Drives |

Rapid Traverse X-axis |

m/min |

5 (Linear Scale) |

| Rapid Traverse Y-axis |

m/min |

5 (Linear Scale) |

| Rapid A-Rotation |

rpm |

40 |

| C-axis Rotation |

deg |

360°(Rotary Encodear) |

| X-Linear Resolution |

mm |

0.001 |

| Y-Linear Resolution |

mm |

0.001 |

| A-Indexing Accuracy |

sec |

20 |

| A-Repeatability Accuracy |

sec |

4 |

| Wheel Spindle |

Grinding Wheel Diameter |

mm |

∅300x∅105x20t |

| Grinding Spindle Speed |

rpm |

3600 |

| Power Required |

KW |

3.7 |

| Dressing Device |

Disk Wheel Diameter |

mm |

∅100x∅50x16t |

| Disk Spindle Speed |

rpm |

1800 |

| Pack Power |

KW |

1.5 |

| Electrical |

Main Voltage |

- |

220V / 60Hz |

| Consumption Power |

KVA |

0.9 |

| Machine Size |

Length x Width |

mm |

2525x3460 |

| Height |

mm |

2000 |

| Weight |

Kg |

9000 |

| Control Technology |

Controller |

- |

FANUC Oi-MF |

Conditional table by models

Development completion -1

Development completion -1 Development completion -2

Development completion -2 Material – Before

Material – Before Material - After

Material - After